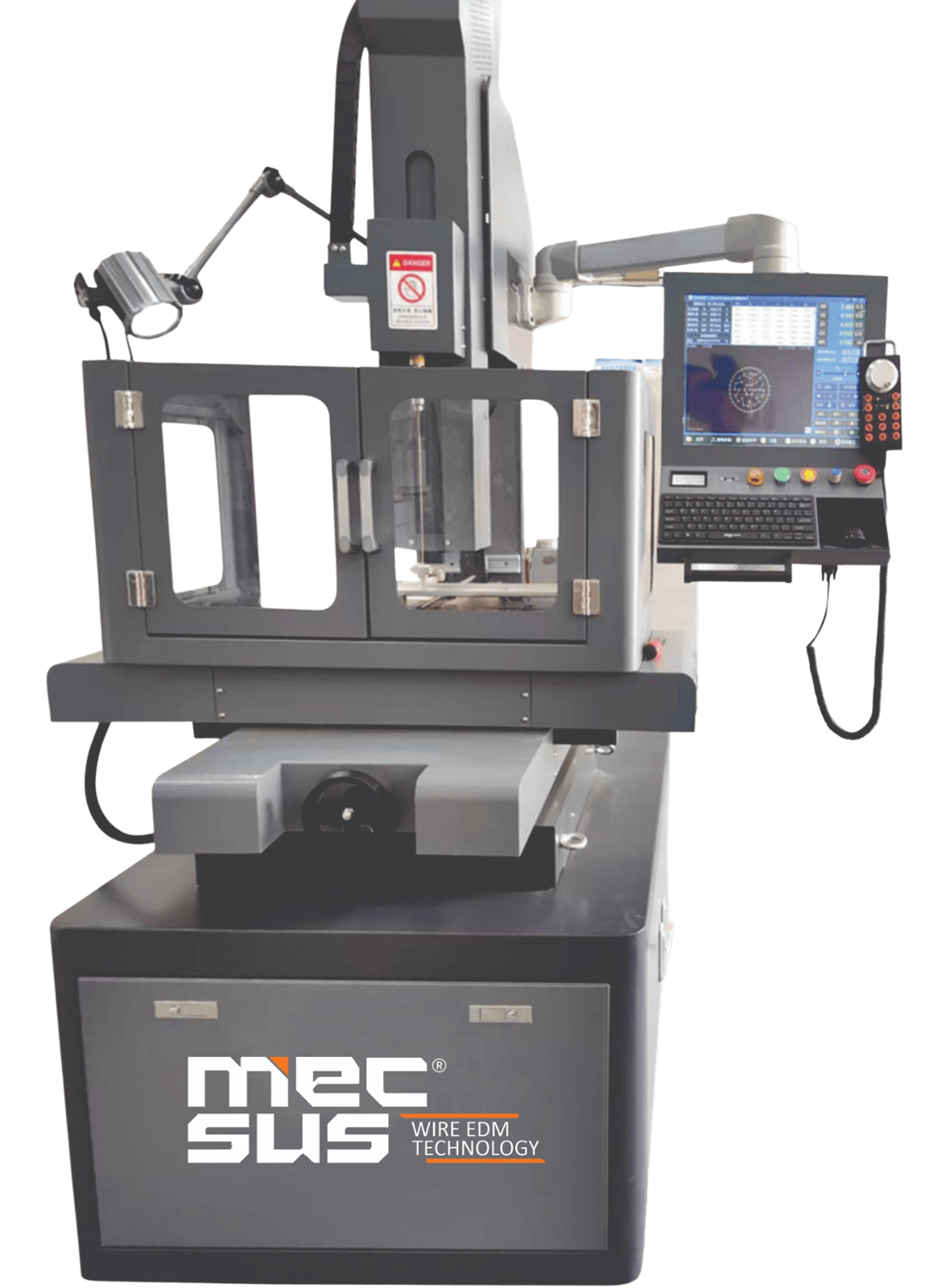

CNC EDM DRIL

A precision machine for deep-hole machining in hard, tough, and conductive materials.

Electrode: Copper/brass/ coated tube

Working principle: High-frequency spark erosion with servo-controlled feed

Flushing: High-pressure water through hollow electrode for cooling & debris removal

Hole size: Ø0.3 – Ø3.0 mm

Depth ratio: Up to 300:1 (e.g., 0.3 mm × 90 mm)

Speed: 1 – 40 mm/min (material dependent)

Key feature: Drills directly on curved or inclined surfaces without pilot holes

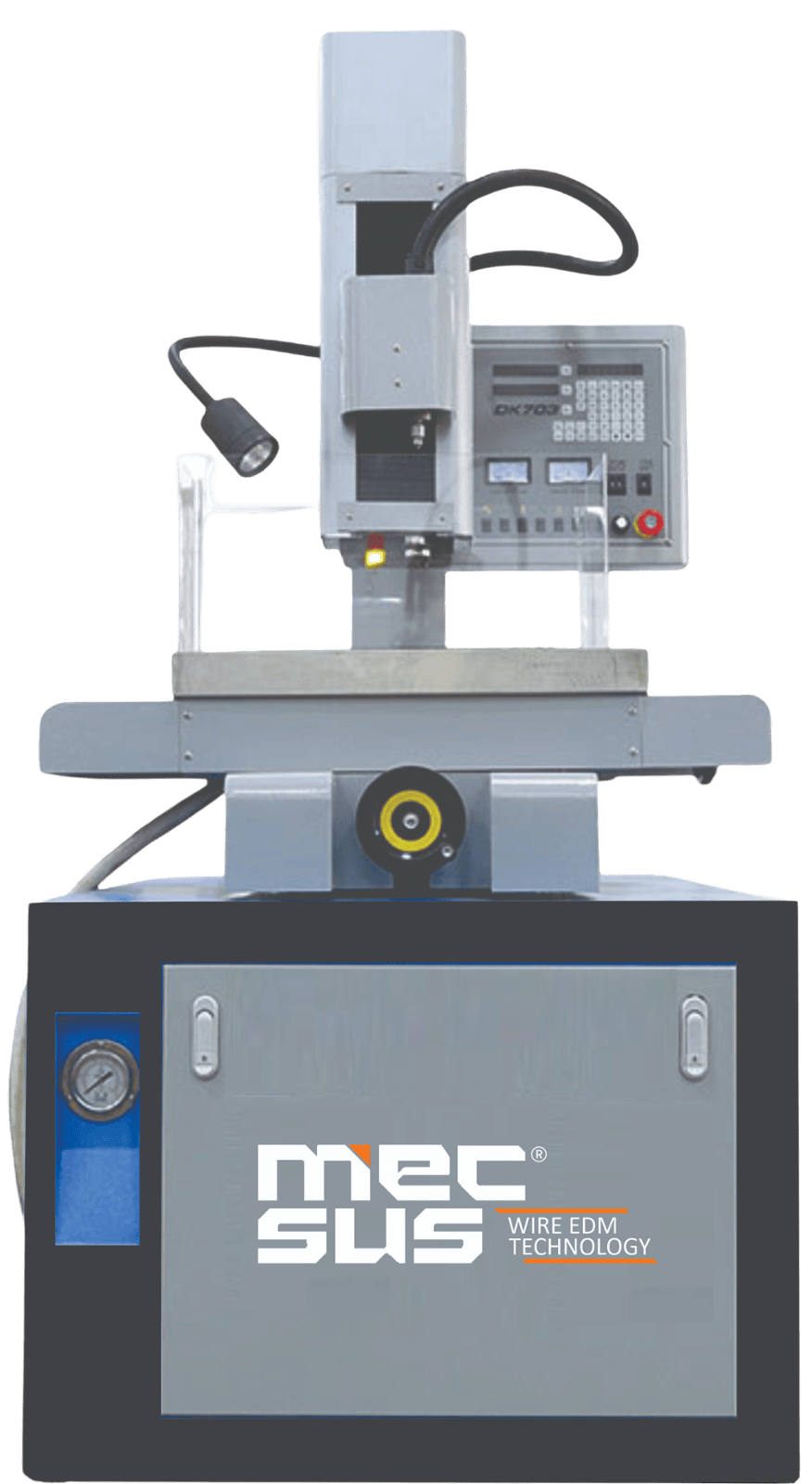

MANUAL EDM DRIL

Machining Aperture – Drills 0.3–3.0 mm holes with depth-to-diameter ratio over 300:1.

Processing Speed & Stroke – Achieves 5–40 mm/min with 300 mm servo stroke and electrode saving.

Material Capability – Machines stainless steel, carbide, copper, aluminum, and other conductive materials.

Surface Penetration – Directly drills on inclined or curved surfaces without slipping.

Servo Lifting System – Double linear guide rail with electric lifting ensures high accuracy.

Spindle Control – Two-speed spindle allows fast back-off and stable fine-electrode processing.

Rotary Head & Flushing – Taiwan rotary head with high-pressure pump provides stable, leak-free flushing.

Worktable Precision – X & Y axes with grating digital display enable accurate hole positioning.