Lower Consumable Costs

Reduced Downtime

Versatile Cutting

Energy Efficiency

Longer Machine Life

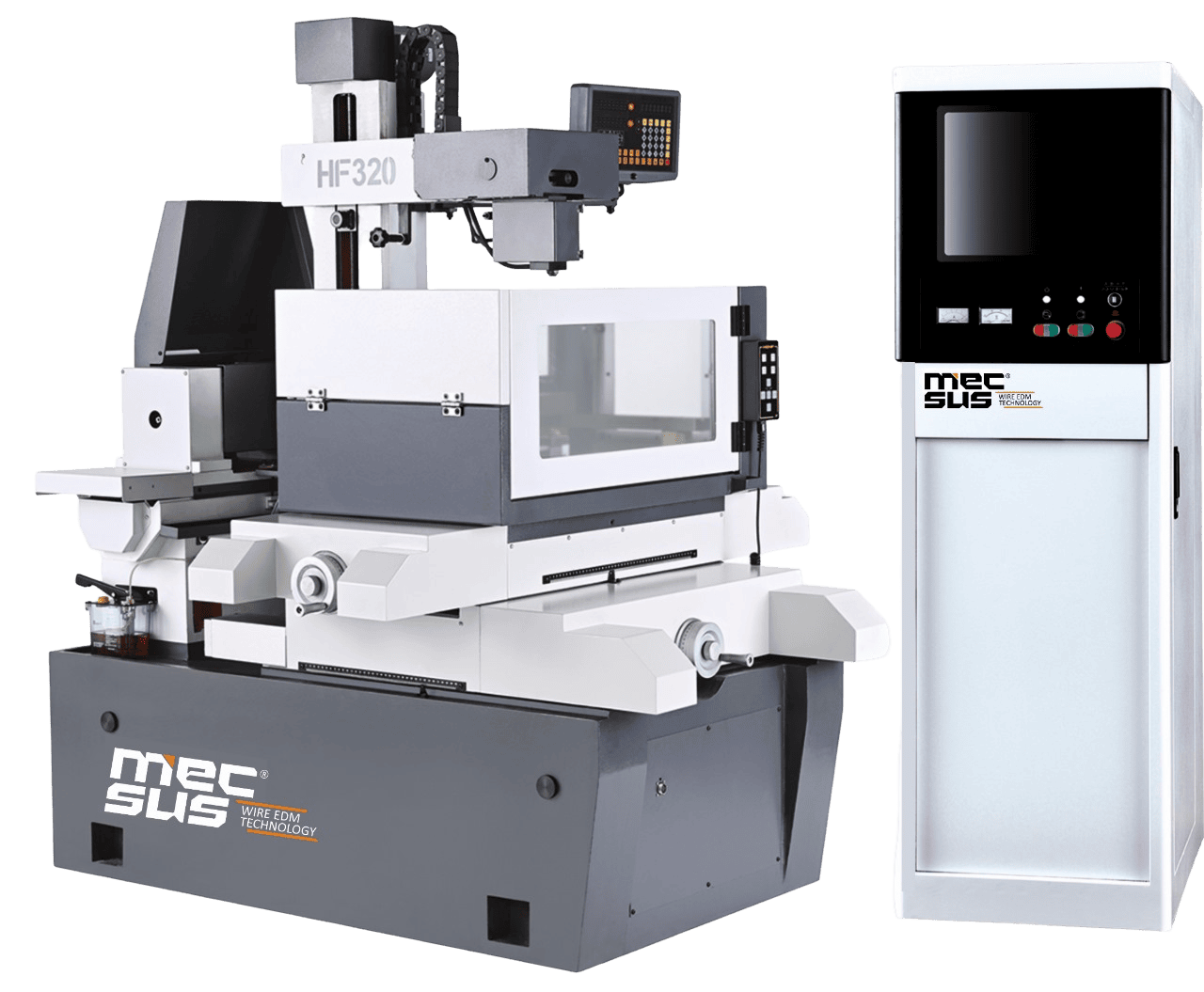

FEATURES

Precision & Quality

Intelligent Pulse Waveform Control – Lower wire wear, better surface finish → reduced consumable costs

Digital Servo Tracking & 4-Axis Linkage – High precision in complex shapes → consistent quality, less rework

Real-Time Trajectory Display– Error prevention → minimal scrap and higher yield

Automation & Operator Efficiency

Graphical Interface – Easy job setup → less training required, faster programming.

Auto Stop After Job & Auto Wire Positioning – Less supervision → operators can multitask. rework

Flexibility & Compatibility

CAD Compatibility – Works with most CAM software → no vendor lock-in.

Adjustable Wire Speed – Optimized cutting → handles different materials & thicknesses easily.

Reliability & Safety

Power Interruption & Wire Break Protection –Resume cutting without restart → less downtime, no wasted parts

Integrated Strong/Weak Circuit Control – Fewer failures → more reliable operations.

Thermal Cycle Pump Cooling– Stable temperature → longer machine life.

Cost & Energy Savings

Advanced Stepper Motor Drive – Energy efficient → lower electricity bills

Auto Shut Down on Completion – No wasted power → saves running cost

Low Maintenance Design– Reduced service expenses

Future-Proof Options

Models with “S” or “E” – Enhanced servo drives + handheld controllers → portable, flexible, precision-friendly upgrades.